During this winter I had great trouble starting my engine. It did not get better as the temps went up so today I finally swapped in a new battery. Now it starts as when it was new :)

From the marking one can guess that the old battery was made in 2016. I used it from summer 2019, until now in 2023. I hope they last better than this on average.The building of a Vans RV-14

6/13/23

9/25/22

Warm-up flight and a mess free oil change

Fall is here and flights are expected to be less regular. I therefore made an oil change despite only having 22 hours on the oil, I like to have fresh oil at the beginning of the cold season.

The numbers are still as they should be, screen shots from my two most used cruise setting, the sight seeing setting and the economy travel setting.

Then it was time for the oil change, using the quick drain an a hose removes all the messiness.

Always good to peak around when the cowling is off, found one loose nut:

6/27/22

6/22/22

Annual inspection and test flight

Yesterday I performed the last parts of the mandatory annual inspection.

Today I made a check flight to make sure that I have not messed up anything. Once again I was made aware of the importance of making a check flight in good conditions after any maintenance.

When taking of, the AOA warning stayed on longer than expected. I did not realize it during the flight but when reviewing the logs I can see that my airspeed indication was a little optimistic, I flew with settings that should give me 120kt IAS but it showed almost 125. When on final, I got the feeling of flying slower than shown and the AOA signal started warning me well above 75kt. I started to suspect something wrong with the static, dynamic or AOA inputs, either a loose line or that water had entered the system during the washing after the last flight. After an uneventful landing and taxi, I shut don the engine and systems and found the problem almost immediately after opening the canopy: One of the static input lines had loosened in the T-connection that splits the input from the static inputs to the G3X-GSU25 adhrs and the G5. The effect being that both the G5 and G3X system got static pressure from within the cockpit. I guess this was a good test, now I know what happens if I use the alternate static pressure valve :)

All is good now and I have just sent in the paperwork and expect to be approved for another year.

9/23/21

Smart glide tested

I finally got around to make another flight to test Smart Glide. I will update this post with a video as soon as I have gotten a approval from the authorities to share this video. (it should not contain anything secret but you never know ;) )

Basically it works as advertised but I´m not so sure it is useful in most scenarios. I will use it if I have engine trouble at high altitude in IMC, for a short while, while I organize myself before manually setting up for an approach.

It has a lot of potential for improvements that could make it close to as useful as Auto Land. The system has all information needed to create and let the autopilot use a visual approach guidance to a runway threshold, using the sink rate you have programmed and accounting for wind. All the pilot would have to do then is to make a final flare :D

Updated with video:

9/15/21

Smart glide.... not tested.

Last evening I updated the G3X Touch system and then got up for a test flight.... just to relize that I forgot to turn the feature on in the configuration.

Testing will have to wait for a while, the airport is closed in the upcoming weekend :(

8/8/21

Scary pre-flight finding

I have had the RV tied down outside on a grass field for a few days (drag racing at my home airfield). While removing the tie-downs I saw a problem.

I always check all flight control surface connections during each daily pre-flight but I now realize that I almost always only check this flap hinge attachment from the bolt head side, I usually never look at it from the nut side. This incident shows that I have to change my walk around routine.

Picture showing the problem:

Washers, nut and lock-pin is missing, how many flight have I done with the missing hardware?

And how it looks after a 5-minute fix:

7/29/21

Data collection for the upcoming Garmin Glide functionality

Garmin will soon give us G3X Touch users a nice new feature for free. In preparation for this I made a flight yesterday to collect the needed data for it. I wanted to verify earlier numbers.

Result from the worst case scenario (Engine still running but without power and prop full forward):

Measured at the best glide speed of 95kt IAS: vs -995fpm

From this you get:

no wind glide ratio 1:9.67

no wind decent angle 5.905 degrees

no wind 1.59NM / 1000 feet agl

no wind 2.85 km / 1000 feet

7/20/21

Time to adjust the fairings

More preparation for painting. Never been happy about how the fairings between the gear leg fairings and the fuselage and the fairings between the gear legs and wheel pants. Time to adjust. I am also making access panels for easier air fill/air pressure testing of the wheels.

7/13/21

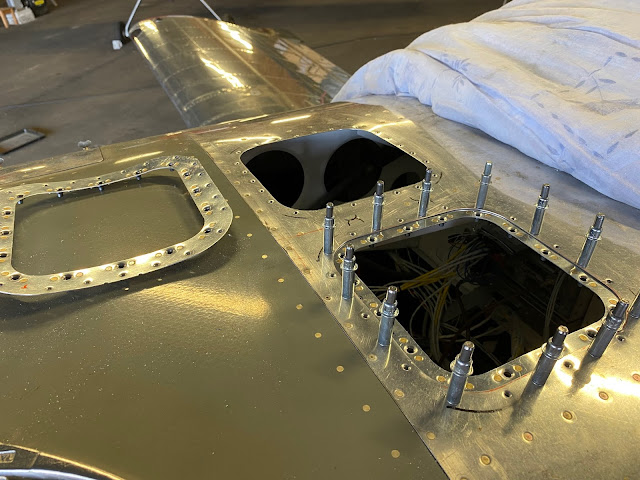

Access Panels, part 2, done?

Another day with many hours in the hangar. in retrospect, I should have gotten me some better cutting wheels for my dremel... Anyway, now the tank sealant is hardening, tomorrow I will hopefully just have a few minutes of cutting away some excess sealant and then I´m done with this task.

I followed tips from different builders and did not drill the #19 holes directly, I first drilled #30 holes so I could use regular clecos to hold things for match drilling.

7/12/21

7/3/21

In preparation for painting

I intend to paint my RV soon. I have three tasks that should be done before that:

- Install new flush door handle from JD Air, pictures from their site

- Install service hatches in front of the canopy

- Make the lower fairings between the gear leg fairings and wheel pants fit better

6/20/21

6/16/21

Annual 2021 part 4, done

Last part involved removing access plates in the fuselage and wings (did not have the phone with me when I was under the wings). and check things out. I found no new problems :)

As all safety critical parts are done, I filled out and sent in the paperwork. Already got an OK reply so I am now good for another year. Only thing left to do is checking/re-greasing the main wheel bearings.

6/15/21

Annual 2021 part 3

The traditional spark plugs also looked good, gap was ok...

6/12/21

Annual 2021 part 2

This Thursday I got around to making a warm-up flight and then change the engine oil. Less mess this time.