Another day with many hours in the hangar. in retrospect, I should have gotten me some better cutting wheels for my dremel... Anyway, now the tank sealant is hardening, tomorrow I will hopefully just have a few minutes of cutting away some excess sealant and then I´m done with this task.

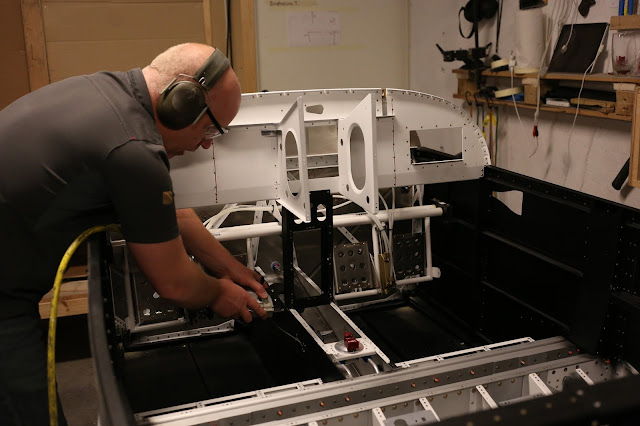

I followed tips from different builders and did not drill the #19 holes directly, I first drilled #30 holes so I could use regular clecos to hold things for match drilling.