At 97 hours and with 30 days to the deadline, it is time to start the annual inspection.

This year I started at the both ends. First I took a look at the front, in general everything firewall forward looked great.Engine controls including the cables still looks like new and all cotter pins are in place :)

There is a small leak between the injector house and the sump, nothing I worry about.

I will remove the magneto to perform two service bulletins in a few days, I checked the timing anyway just to see the status. It has creeped a bit, it should go off at 20 degrees before tdc but it was triggered at 22-23 degrees. I set it back to 20 for now. I have not seen any difference in the logs between flights directly after the last annual when I knew it was at 20 and the flights that have been flown recently. Not surprising as at all setting but full power the magneto will lag significantly behind the e-mag.

Speaking of the e-mag, a small cable that sits between two poles on the connector was broken, allowing the e-mag to use the more aggressive timing scheme.... again I have not noticed any downside to this in the logs but I fixed it as I want a greater margin and the fuel savings from the more aggressive timing is barley noticeable.

To be done FW-forward is to check&clean or exchange spark plugs, clean the air filter, perform the mag SBs and do an oil&oil filter change..

While at the front I also checked the prop, gear legs, fairings, brake lines and tires. All looked good, I plan to re-grease the wheel bearings but it might have to wait until slightly after the annual as I do not have any good lifting solutions at the hangar now.

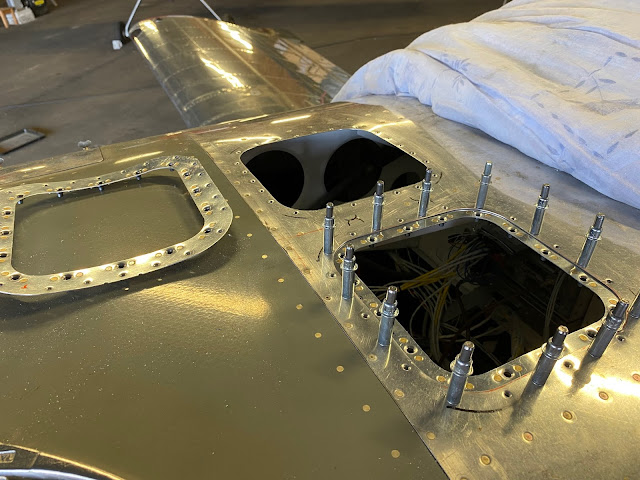

I then removed some fairings and panels at the back. Looks great, nothing has come loose and it looks just as clean or dirty as it did during final assembly.